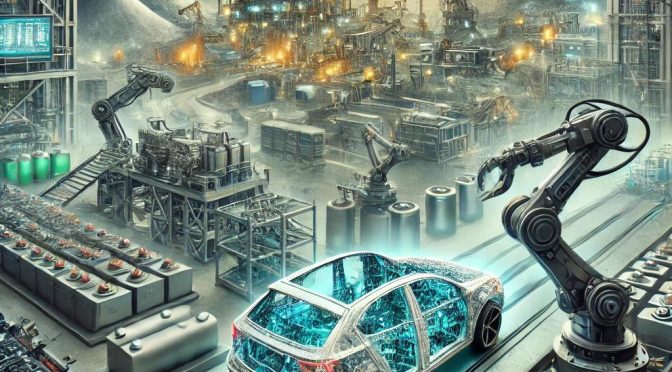

As the world shifts towards greener transportation, electric vehicles (EVs) are seen as a crucial solution to reducing carbon emissions. However, while EVs offer a cleaner alternative to gasoline-powered cars during their lifetime, the production process of a single electric vehicle has significant environmental consequences. From raw material extraction to battery manufacturing and assembly, the ecological footprint of EV production is substantial.

1. Raw Material Extraction

The foundation of any EV lies in its battery, which is primarily composed of lithium, cobalt, nickel, and graphite. Extracting these materials comes with a high environmental cost:

- Lithium Mining: This process often takes place in regions like Australia, Chile, and Argentina, where it requires vast amounts of water. In Chile’s Atacama Desert, lithium mining is responsible for consuming nearly 65% of the region’s water supply, severely impacting local ecosystems and communities.

- Cobalt Extraction: Cobalt is primarily mined in the Democratic Republic of the Congo (DRC), where mining activities contribute to deforestation, habitat destruction, and pollution of water sources. Additionally, human rights concerns, including child labor, further complicate its ethical footprint.

- Nickel & Graphite: Nickel mining leads to significant deforestation and soil erosion, while graphite production is known for emitting harmful dust pollution.

2. Energy-Intensive Battery Manufacturing

The production of lithium-ion batteries is an energy-intensive process. Studies estimate that producing an EV battery pack (especially for long-range models) generates between 50 to 100 kg of CO₂ per kWh of battery capacity. This means that a Tesla Model 3 battery (75 kWh) alone could account for up to 7.5 tons of CO₂ emissions before the car even hits the road.

3. Vehicle Manufacturing and Assembly

Like conventional vehicles, EV production requires a significant amount of energy for manufacturing the frame, electronics, and other components. The production of aluminum and steel used in EVs emits substantial greenhouse gases. Furthermore, due to the added weight of battery packs, some EVs require more structural reinforcement, leading to higher material consumption than traditional gasoline vehicles.

4. Supply Chain and Transportation Emissions

The supply chain for EV components is highly globalized, with raw materials sourced from one continent, processed in another, and assembled in yet another. Transporting these materials and parts across the globe adds to the overall carbon footprint of EV production. On average, supply chain emissions can contribute an additional 2 to 5 tons of CO₂ per vehicle.

5. Water Consumption and Pollution

Beyond carbon emissions, EV production significantly impacts water resources. Lithium mining alone requires approximately 500,000 gallons of water per metric ton of lithium extracted. Additionally, industrial wastewater from mining and battery production can contain hazardous chemicals such as sulfuric acid and heavy metals, which, if not properly managed, pollute local waterways.

6. The End-of-Life Challenge: Recycling and Disposal

While EVs have a lower operational footprint, their long-term sustainability depends on how well their components, particularly batteries, are recycled. Currently, battery recycling infrastructure is still developing, and less than 5% of lithium-ion batteries are fully recycled. If not properly disposed of, battery waste can contribute to toxic environmental contamination.

Conclusion: A Step Forward, but with Costs

While EVs significantly reduce emissions during operation, their production still has a substantial environmental impact. However, advancements in battery recycling, cleaner mining practices, and more efficient manufacturing are helping to reduce this footprint. As technology progresses, the goal should be to make EV production as sustainable as their use.

Thus, while electric vehicles are a key part of the solution to climate change, understanding and mitigating the environmental impact of their production is essential for a truly green future.